SS 316 Round Pipe Manufacturers In India

- Home

- Stainless Steel

DESCRIPTION

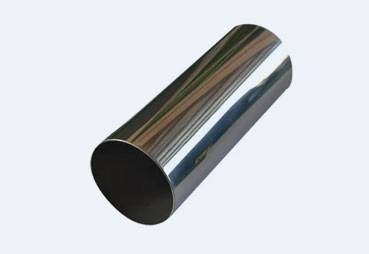

Stainless steel is one of the most popular materials used in piping applications due to its durability, resistance to corrosion, and low maintenance requirements. Among the different types of stainless steel pipes available, Stainless Steel 316 Round Pipes stand out for their high strength, versatility, and superior resistance to corrosive environments.

316 Stainless Steel Round Pipe, 316 Steel Round Pipes, 316 Stainless Steel Round Pipe Weight Chart, SS 316 Round Pipe, SS 316 Round Pipe Manufacturers in India.

Stainless Steel 316 Round Pipes are available in different types distinguished by composition and manufacturing process. The most common types are seamless pipes and welded pipes. Seamless pipes are produced using extrusion and piercing processes that create a seamless material without seams or joints. Welded pipes, conversely, are formed by welding two or more pieces of steel together, resulting in a welded seam. Both types of pipes have advantages and disadvantages, depending on the specific application and requirements.

+91 9820010544

Stainless Steel 316 Round Pipe Price, 316 SS Round Pipe Price, 316 Round SS Pipe, SS 316 Pipe Round, 316 Round Stainless Steel Pipe, 316 Stainless Steel Round Pipe Manufacturers in Mumbai.

Stainless Steel 316 Round Pipes are used in various applications across various industries, including chemical processing, oil and gas, marine, automotive, and construction. Due to their superior corrosion resistance, these pipes are particularly suited for applications that involve exposure to harsh environments, such as high temperatures, acids, alkalis, and seawater. They are used for transporting liquids, gases, and solids and can also be used as structural components in buildings and bridges.

Some of the most common uses of Stainless Steel 316 Round Pipes include chemical processing, oil and gas processing, seawater handling, wastewater treatment, food and beverage processing, pharmaceuticals, and medical devices. In chemical processing, these pipes are used to transport highly corrosive chemicals and acids. In contrast, in oil and gas processing, they are used for transporting crude oil, natural gas, and refined products. In marine applications, they are used for seawater handling and cooling systems. In the food and beverage industry, they are used for transporting liquid and gases; in the pharmaceutical industry, they are used for producing medical devices and implants.

The benefits of Stainless Steel 316 Round Pipes are many. They have high strength and durability, making them resistant to damage and wear. They are corrosion-resistant, which makes them ideal for use in harsh environments. They are easy to clean and maintain, reducing contamination risk. They are also non-toxic and inert, making them suitable for food and medical applications. They are versatile and can be designed to meet specific requirements, such as size, shape, and mechanical properties. Stainless Steel 316 Round Pipes are versatile, strong, and highly resistant to corrosion, making them ideal for use in various applications across numerous industries.

316 Stainless Steel Round Pipe Specifications

| Specifications | ASTM A312 / ASME SA312 |

| Dimensions | ASTM, ASME, and API |

| Seamless Pipe Size | 1/2″ NB – 16″ NB |

| Welded Pipe Size | 1/8″NB TO 30″NB IN |

| Thickness | 0.35 mm – 50 mm |

| Schedule | SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, SCH 80S, SCH60, SCH80, SCH120, SCH140, SCH160, SCH XXS, SCH XS |

| Type | Seamless Round Pipes, ERW Round Pipes, Welded Round Pipe, Fabricated Round Pipes, Electropolished Round Pipe, Polished Round Pipe |

| Form | Round |

| Length | Single Random, Double Random & Required Length. |

| End | Plain End, Beveled End, Treaded End |

| Value Added Service | Draw & Expansion as per required Size & Length Polish (Electro & Commercial) Heat Treatment Bending Annealed & Pickled Sand Blasting Machining Etc. |

“ Get Free Sample of 316 Stainless Steel Round Pipe, We Are Reliable Jindal 316 Stainless Steel Round Pipe stockist. Contact us if you are looking to buy Stainless Steel 316 Round Pipes.”

SS 316 Round Pipe Equivalent Material

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

Types Of Stainless Steel 316 Round Pipes

We Provide The Best Quality UNS S31600 Thick And Thin Wall Round Pipe, Stockist & supplier of 1.4436 Round Pipe and Schedule 40 316 Stainless Steel Round Pipe in Mumbai.

Jindal SS 316 Round Pipe Price List

Check Standard Size and Weight Chart Of 316 SS Round Pipe

Wide Stock Of Stainless Steel 316 Round Pipe In India

- 316 Stainless Steel Round Pipe Dimensions

- SS 316 Round Pipe Suppliers in Mumbai

- Electropolished Stainless Steel 316 Round Pipe

- UNS S31600 Round Pipes

- 316 Stainless Steel Round Pipe Manufacturers

- Stainless Steel 316 Round Pipe Manufacturers in Mumbai

- 316 SS Round Pipe

- Austenitic Stainless Steel 316 Round Pipe

- Stainless Steel 316 Round Pipe Manufacturers in India

- SS 316 Round Pipes

- SS 316 Round Pipe HSN Code

- Stainless Steel Round Pipe ASTM A312 TP316

- SS 316 Sch 10 Round Pipe Weight Per Meter

- Stainless Steel 316 Round Pipe Sizes

- Weight Of SS 316 Round Pipe

- SS 316 Round Pipe Suppliers in India

- SS 316 Round Pipe Manufacturers in India

- Stainless Steel 316 Round Pipe Suppliers in India

- Schedule 40 316 Stainless Steel Round Pipe

- ASTM A312 TP316 Stainless Steel Round Pipe

- 316 Stainless Steel Round Pipe Near Me

- 316 Stainless Steel Round Pipe Pressure Rating

- 1.4436 Round Pipe

- SS 316 Schedule 40 Round Pipe Pressure Rating

- Stainless Steel 316 Round Pipe Suppliers in Mumbai

- 16 Gauge 316 Stainless Steel Round Pipe

- Jindal SS 316 Round Pipe Weight Chart

- SS 316 Round Pipe Thickness Chart

- 316 Steel Round Pipe

- Large Diameter Stainless Steel 316 Round Pipe

- Jindal 316 Stainless Steel Round Pipe

- ASME SA312 Stainless Steel 316 Round Pipe

- 316 Stainless Steel Round Pipe Pressure Rating Chart

- SS 316 Round Pipe Price

- Schedule 10 316 Stainless Steel Round Pipe Pressure Rating

- SS 316 16 Gauge Round Pipe Weight

- SS 316 Round Pipe Manufacturers in Mumbai

SS 316 Round Pipe Chemical Composition

Ni

Nickel

10.00 - 14.00

Mo

Molybdenum

2.00 - 3.00

Cr

Chromium

16.00 - 18.00

Fe

Iron

67.845 min

W

Tungsten

-

Co

Cobalt

-

Mn

Manganese

2.0 max

N

Nitrogen

-

Si

Silcon

1.0 max

P

Phosphorus

0.045 max

S

Sulfur

0.030 max

C

Carbon

0.08 max

316 Stainless Steel Round Pipe Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316 | 515 | 205 | 40 | 95 | 217 |

SS 316 Round Pipe Testing Methods

316 Stainless Steel Round Pipe Applications

US $1200-5200 / Metric Ton

US $1440-5400 / Metric Ton

US $800-8200 / Metric Ton

US $1366-3818 / Ton

US $1500-2850 / Ton

US $2300-3500 / Ton

US $2700-3600 / Ton

US $1800-4200 / Kilogram

US $1070-1520 / Ton

US $1700-5500 / Ton

US $1350-3700 / Ton

US $800-2800 / Ton

US $2-70 / Piece