Quality

Scan & Examine

Stainless Steel Materials

As part of Rico's comprehensive Quality Control program, there have been targeted investments in the equipments and machines to ensure Stainless Steel Welded Pipes & Tube orders are duly fulfilled.

Rico has a dedicated team that takes care of rigorous quality management from placing the order to the receipt right through the shipping, hence, the entire process control is implemented systematically. Optical devices and analog measuring instruments like caliper, alloy analyzer and other gauges are used for the inspection. Both the heat number & lot controls are noted to ensure the total traceability. Additionally, Positive-Material-Identification (PMI) is tested on all Stainless Steel materials after receiving and before leaving the warehouse to ensure no material mix has occurred.

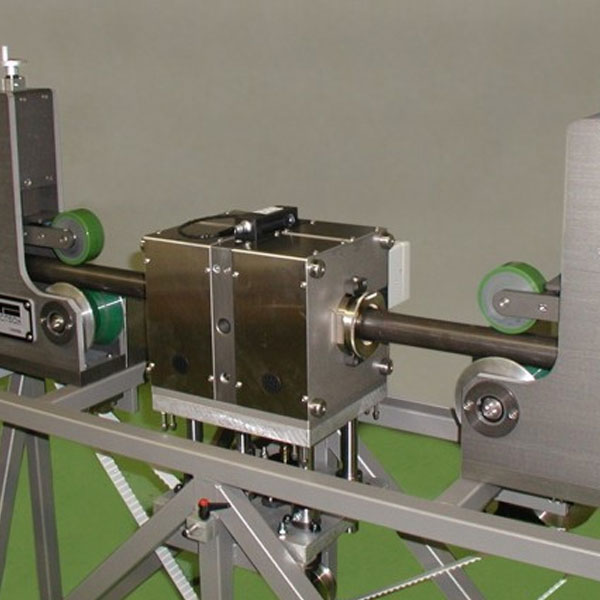

EDDY CURRENT TEST

View me

EDDY CURRENT TEST

To identify the discontinuities on the Stainless Steel Tubes that may impact structural integrity & productivity of the operation.

HARDNESS TEST

View me

HARDNESS TEST

To understand the ability of the Stainless Steel Pipes to resist the impact of external force and maintain its durability

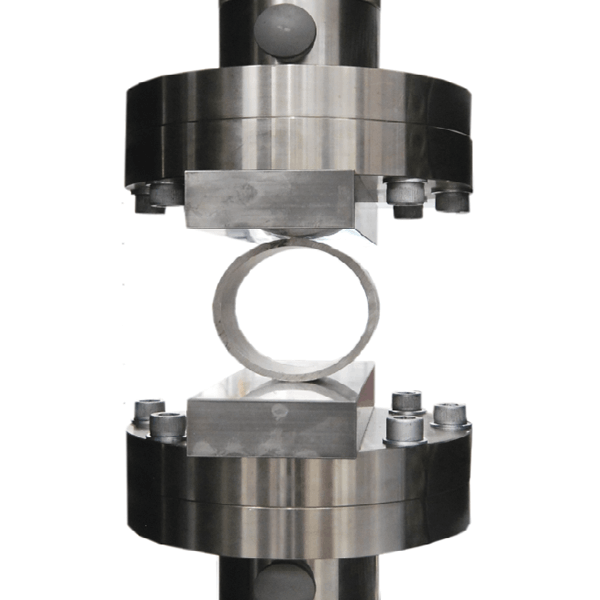

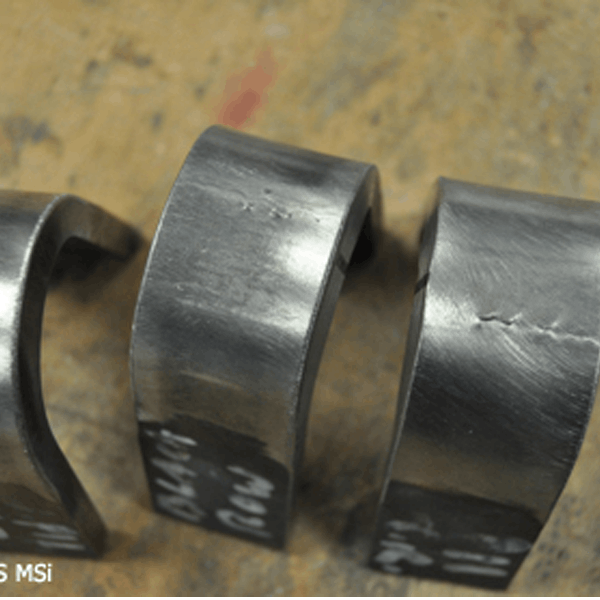

WELD TESTING

View me

WELD TESTING

For Pipe Weld Test, methods used are X-Ray, Electromagnetic and Macro-Etch Tests.

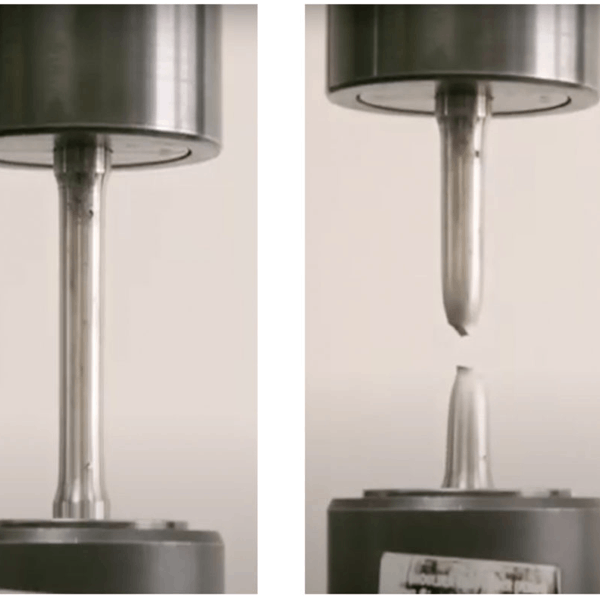

TENSILE TEST

View me

TENSILE TEST

determines the peak stress, yield strength, elongation and the ductility under the stress

FLATTENING TEST

View me

FLATTENING TEST

To understand the plastic deformation capacity of Stainless STeel seamless tubes in different conditions, flattening test is conducted.

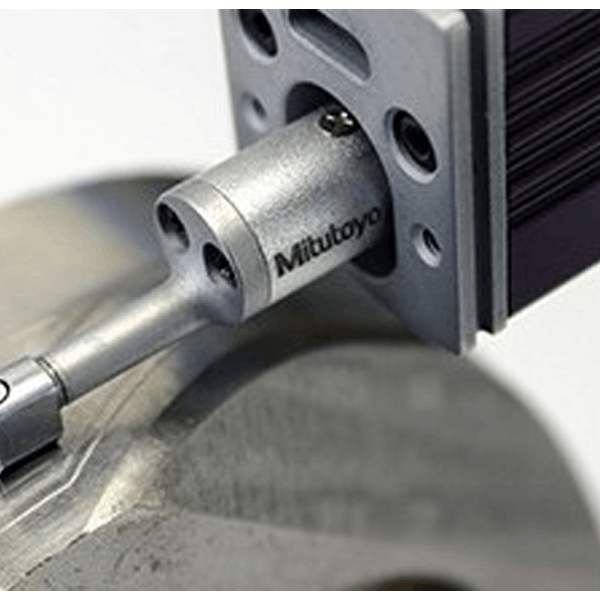

SURFACE FINISH TESTS

View me

SURFACE FINISH TESTS

To measure deviations in the surface texture of SS Tubes, a profilometer is used that has a diamond-tipped stylus which reacts with the variations on the surface texture.

PMI TEST

View me

PMI TEST

PMI helps with the signs of material mix which possibly be bars or components that differ in size or color.

BEND TEST

View me

BEND TEST

Bending makes it visually easy to recognise discontinuities, hence, the stainless steel tubes are put under load and inspected for the same.