SS 316 Welded Pipe Stockist In India

- Home

- Stainless Steel

DESCRIPTION

Stainless steel 316 is one of the most widely used materials in welding pipes and tubes. This steel type is highly corrosion resistant, making it an ideal choice for applications in harsh environments. Additionally, stainless steel 316 provides excellent strength and durability, making it suitable for various industrial and commercial applications.

SS 316 Stainless Steel Welded Pipe, Welding 316 Stainless Steel Pipe, ASTM 316 Stainless Steel Welded Pipe, 316 Stainless Steel Welded Pipe, SS 316 Welded Pipe Manufacturers in India.

There are two main types of Stainless Steel 316 Welded Pipes and Tubes: seamless and welded. Seamless pipes and tubes are produced by piercing a solid steel billet to form a hollow section. These pipes are then rolled to the required size and shape. Welded pipes and tubes, on the other hand, are produced by welding the steel strip or plate into a tubular shape. The tubes are then welded together to create a continuous length.

+91 9820010544

316 Stainless Steel Welded Tube, SS 316 Welded Pipe, 316 SS Welded Tubes, SS 316 Welded Pipe Manufacturers In India, SS 316 Welded Tubes, 316 SS Welded Tubing, 316 SS Welded Tubes, 316 Stainless Steel Welded Tubes, SS 316 Welded Pipe Supplier, 316 Stainless Steel Welded Tubes Manufacturers in Mumbai.

Stainless steel 316 welded pipes and tubes are used in various industries, including oil and gas, chemical processing, and power generation. They are also used in the food and beverage industry, where high levels of hygiene are required. These pipes and tubes are suitable for both high and low-temperature applications and in applications where high pressure is required.

Stainless steel 316 welded pipes and tubes are used for various purposes, including transporting fluids and gases under high pressure and in harsh environments. They are also used as structural components in buildings and bridges, as well as in the manufacturing of medical equipment and appliances. Stainless steel 316 is ideal for manufacturing heat exchangers, where heat transfer is required in a highly corrosive environment.

One of the main benefits of using stainless steel 316 welded pipes and tubes is the material's resistance to corrosion. That makes it ideal for use in harsh environments, such as the oil and gas industry, where exposure to saltwater and other corrosive elements can cause significant damage. Stainless steel 316 is highly durable and resistant to wear and tear, making it an ideal choice for industrial applications where the pipes and tubes will be subject to high-stress levels.

Another benefit of using stainless steel 316 welded pipes and tubes is that it is elementary to maintain. Unlike other materials, it does not require regular cleaning or polishing to maintain its appearance. Stainless steel 316 is also very easy to weld, which means it can be used in a wide range of applications where welding is required.

Stainless steel 316 welded pipes and tubes are a versatile, highly durable, and cost-effective solution for various industrial and commercial applications. They give excellent resistance to corrosion, high strength, and durability, making them ideal for use in harsh environments. Moreover, they are highly versatile, and their ease of maintenance and handling make them an excellent choice for various applications requiring high strength and corrosion and wear resistance.

SS 316 ERW Pipe Specification

| Specifications | ASTM A312, A269, A249 / ASME SA 312, SA 269, SA 249 |

| Dimensions | ASTM, ASME, and API |

| Welded Pipe Size | 1/2″ NB – 16″ NB |

| Welded Tube Size | 1/8" To 30″NB Inch OD: 0.35 to 6.35mm |

| Thickness | 0.35 mm – 50 mm |

| Specialized in | Large Diameter Pipe Size |

| Schedule | SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, SCH 80S, SCH60, SCH80, SCH120, SCH140, SCH160, SCH XXS, SCH XS |

| Type | Welded Pipes, Welded Tubes |

| Form | Round, Square, Hydraulic, U Shape, Rectangular, Pan Cake Coils, Coiled, Hex, Honed, Etc |

| Length | Single Random, Double Random & Required Length. |

| End | Plain End, Beveled End, Treaded End |

| Value Added Service | Draw & Expansion as per required Size & Length Polish (Electro & Commercial) Heat Treatment Bending Annealed & Pickled Sand Blasting Machining Etc. |

“ Get Free Sample of 316 Stainless Steel Welded Pipe, We Are Reliable 316 SS Welded Pipes stockist. Contact us if you are looking to buy Stainless Steel 316 Welded Tubes.”

SS 316 Welded Pipe Equivalent Material

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

Types Of Stainless Steel 316 Welded Pipes

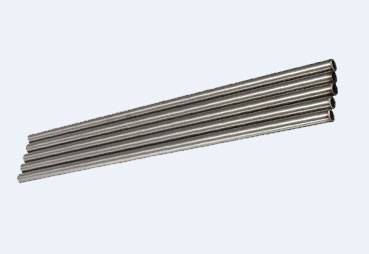

SS 316 Welded Round Pipes

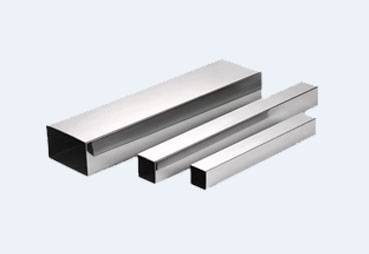

SS 316 Welded Square Pipe

SS 316 Welded Square Tubes

SS 316 Welded Rectangular Pipe

SS 316 Welded Pipes

SS 316 Polished Welded Pipe

SS 316 Welded Rectangular Tubes

SS 316 ERW Pipes

SS 316 ERW Tube

We Provide The Best Quality UNS S31600 Welded, Square and Rectangular Pipes Stockist & supplier of 1.4401 Stainless Steel Welded Tubing and Large 316 Stainless Steel Welded Tubing in Mumbai.

Jindal SS 316 Welded Pipe Price List

Check Standard Size and Weight Chart Of 316 SS Welded Tube

Wide Stock Of Stainless Steel 316 Welded Pipe In India

- SS 316 Welded Pipe Suppliers in India

- ASTM A269 TP 316 Stainless Steel Welded Tubes

- SS 316 16 Gauge Welded Pipe Weight

- Stainless Steel 316 Large Diameter Welded Pipe

- Stainless Steel 316 Welded Tube Suppliers in India

- SS 316 Welded Pipe Price Per Meter

- SS 316 Welded Tube Manufacturers in Mumbai

- Stainless Steel 316 Welded Pipes Price List

- 316 SS Welded Tube

- 316 Stainless Steel Welded Pipe Pressure Rating Chart

- ASTM A249 316 Stainless Steel Welded Tube

- Schedule 40 316 Stainless Steel Welded Pipe

- Stainless Steel 316 Welded Tubing

- 316 Stainless Steel Welded Tubing Near Me

- 316 SS Welded Pipe Price

- 316 SS Round Welded Pipe

- 316 Cold Drawn Welded Stainless Steel Pipe

- 316 Stainless Steel Welded Pipe Manufacturers

- ASME SA312 TP316 SS Welded Thin Wall Pipe

- ASTM A312 TP316 Stainless Steel Welded Pipe

- 16 Gauge 316 Stainless Steel Welded Pipe

- SUS 316 High Pressure Welded Pipes

- ASME SA312 Stainless Steel 316 Welded Pipe

- 316 Stainless Steel Welded Tube Manufacturers in India

- Stainless Steel 316 Welded Pipe Suppliers in Mumbai

- SS 316 Welded Pipe Suppliers in Mumbai

- UNS S31600 Welded Pipes

- 316 SS Welded Tube Manufacturers in India

- Sainless Steel 316 Welded Pipes Supplier

- 1.4401 Thick Walled SS 316 Welded Pipe

- Grade 316 Welded Stainless Steel Pipe

- Jindal SS 316 Welded Pipe Weight Chart

- SS 316 ERW Pipe Specification

- SS 316 Welded Pipe Schedule Chart

- SS 316 Welded Tubing Price Per Kg

- Stainless Steel 316 Welded Pipe Manufacturers in Mumbai

- SS 316 Welded Pipe Size Chart

- SS 316 Welded Pipe HSN Code

- Stainless Steel 316 Welded Pipes Sizes

- 316 Stainless Steel Welded Tube Price

SS 316 Welded Pipe Chemical Composition

Ni

Nickel

10.00 - 14.00

Mo

Molybdenum

2.00 - 3.00

Cr

Chromium

16.00 - 18.00

Fe

Iron

67.845 min

W

Tungsten

-

Co

Cobalt

-

Mn

Manganese

2.0 max

N

Nitrogen

-

Si

Silcon

1.0 max

P

Phosphorus

0.045 max

S

Sulfur

0.030 max

C

Carbon

0.08 max

316 Stainless Steel Welded Pipe Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) / 1399 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

SS 316 Welded Pipe Testing Methods

316 Stainless Steel Welded Tubing Applications

US $220-2630 / Ton

US $1260-1470 / Ton

US $501-3001 / Metric Ton

US $2010-2630 / Ton

US $3-60 / Piece

US $1230-5066 / Ton

US $1356-3388 / Ton

US $2720-3630 / Ton

US $1230-4301 / Kilogram

US $1610-3303 / Ton

US $1770-5500 / Metric Ton

US $2020-6030 / Metric Ton

US $2310-3603 / Ton